From electrical switches and solar panels to chemical-producing catalysts and medical equipment, silver is an essential component in many industries. Its unique properties make it nearly impossible to substitute and its uses span a wide range of applications.

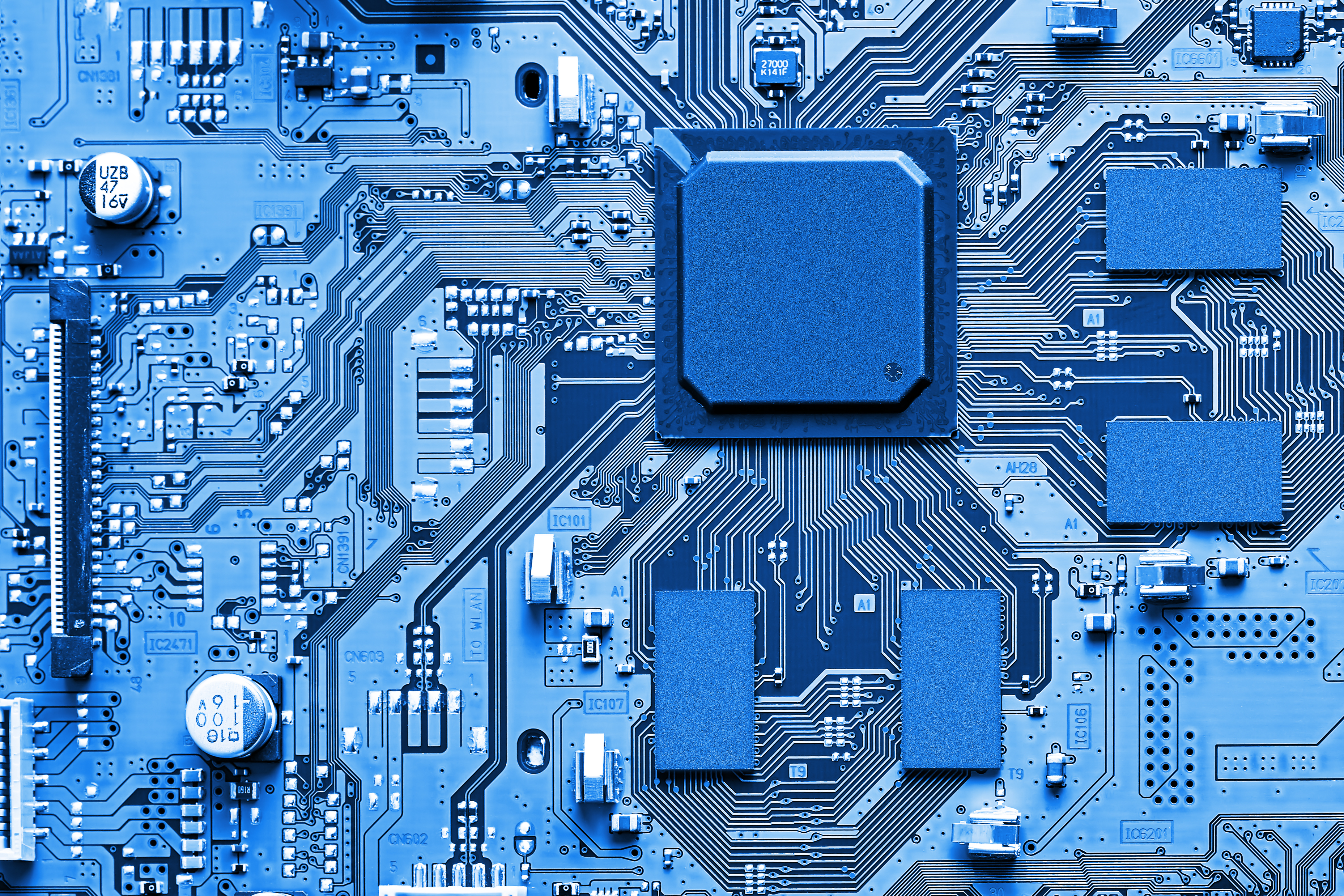

Almost every computer, mobile phone, automobile and appliance contains silver. It is the perfect substance for coating electrical contacts – like those in printed circuit boards and switches – because of its high electrical conductivity and durability. Painting silver ink on any non-metal surface provides an electrical pathway, eliminating the need for wires. For example, Radio Frequency Identification Device (RFID) chips with their tiny, thin antennas made of sprayed-on silver, are replacing bar codes on many items in supermarkets and supply chain inventories. Slender silver wires can also be used as filaments-feed for 3D printers to produce intricate items.

Almost every computer, mobile phone, automobile and appliance contains silver. It is the perfect substance for coating electrical contacts – like those in printed circuit boards – because of its high electrical conductivity and durability. Painting silver ink on any non-metal surface provides an electrical pathway, eliminating the need for wires. For example, Radio Frequency Identification Device (RFID) chips are replacing bar codes on many items in supermarkets and supply chain inventories. The chips’ paper-thin antennas consist of sprayed-on silver.

Silver and Solar Technology

Silver plays a vital role in the production of solar cells and the transmission of electricity that they produce.

Silver’s use in Photovoltaic (PV) power is the leading current source of green electricity. Higher than expected photovoltaic capacity and faster adoption of new-generation solar cells raised global electrical and electronics demand by 4 percent in 2024. This gain reflects silver’s essential and growing use in PV, which recorded a record high of 197.6 million ounces last year, posting a record.

How is silver used in solar cells? Silver powder is turned into a paste which is then loaded onto a silicon wafer. When light strikes the wafer, electrons are released and the silver – the world’s best conductor – carries the electricity for immediate use or into storage batteries for later consumption.

Silver in Electronics

Silver – the world’s best metal conductor of electricity – is found in virtually every electronic device from light switches to mobile phones to supercomputers used for Artificial Intelligence.

Silver in electronics and electrical demand hit another record high last year, growing 4 percent to 465.6 million ounces. Underpinning these overall gains was the limited scale of thrifting and substitution, as silver remains irreplaceable in many applications. At the same time, other silver-related applications, including power grid construction and automotive electrification, contributed to the gains.

Silver membrane switches, which require only a light touch, are used in buttons on televisions, telephones, microwave ovens, children’s toys and computer keyboards. These switches are highly reliable and last for millions of on/off cycles.

For printed circuit boards used in consumer items from mobile phones to computers, silver-based inks and films are applied to composite boards to create electrical pathways. Similarly, silver-based inks produce RFID tags (radio frequency identification), antennas used in hundreds of millions of products to prevent theft and allow easy inventory control.

RFID’s are also used in prepaid toll road passes and keyless locks. Many plasma display panels are also fabricated using silver. In addition, the evolving and growing 5G mobile phone network relies on the excellent electrical conductivity of silver.

Silver-Oxide batteries are also used extensively in applications that require a high energy-to-weight ratio, a multiyear shelf life, as well as in button batteries for products such as door bells, toys and hearing aids.

Silver Catalysts

Because of its unique chemical properties silver is a commonly-used catalyst that is vital for producing two major industrial chemicals: ethylene oxide and formaldehyde. Both of these chemicals are crucial elements to everyday items such plastics, adhesives, carpets, textiles, antifreeze and even clothing.

Because silver is not effected by the reaction, it is almost completely recovered after use.

Nearly 10 million ounces of silver are needed each year to produce ethylene oxide. Ethylene oxide is the foundation for plastics including polyester, a textile used in both mainstream fashion and specialty clothing. This same substance is an ingredient in molded items such as insulating handles for stoves, key tops for computers, electrical control knobs, domestic appliance components, and electrical connector housings. About 25% of ethylene oxide production is used to manufacture antifreeze coolant for automobiles and other vehicles.

Silver catalysts are also vital to manufactoring formaldehyde, a chemical produced from methanol. It is the building block of solid plastics adhesives, laminating resins for construction plywood and particle board. Formaldehyde also helps to produce finishes for paper and electronic equipment, textiles, surface coatings that resist heat and scratches, dinnerware and buttons, casings for appliances, handles and knobs, packaging materials, automotive parts, thermal and electrical insulating materials, toys and many other products.

For more information on silver and catalysis, please see our Silver Catalysis Backgrounder .

Silver in Brazing and Soldering

Metal pieces such as pipes, faucets, ducts and electrical wires are usually joined together either by brazing or soldering, similar processes based on how much heat is applied to the junction. Without the addition of silver none of these connections would be as strong, leakproof, corrosion resistant or as electrically conductive as the original materials.

While people often confuse brazing and soldering the difference is that brazing requires temperatures above 450 degrees Celsius while soldering is performed at temperatures below 450 degrees Celsius. Either way, silver is an essential part of each process.

Silver-tin solders are used for bonding copper pipe in homes, where they not only eliminate harmful lead-based solders, but also provide the piping with silver’s natural antibacterial action. Major faucet manufacturers use silver-based solder to incorporate these advantages and refrigerator manufacturers use silver-based solder to provide the flexibility required for constant changes in the temperature of cooling tubes.

In 2006, the Restriction of Hazardous Substances (RoHS) Directive took effect in the European Union (EU) and banned all products containing more than a trace amount of lead and other hazardous substances. This is putting an end to lead-based solders (though there are exceptions) which had contained lead and tin and replaced it mainly with silver-tin-copper solders which contain about 45% silver.

Silver brazing alloys are used in everything from air-conditioning and refrigeration to electric power distribution. They are also crucial in the automobile and aerospace industries. It is especially useful in joining different metals with high melting points.

Brazing and alloys accounted for 52.9 million ounces of silver in 2023 representing a 3 percent decrease over 2023.

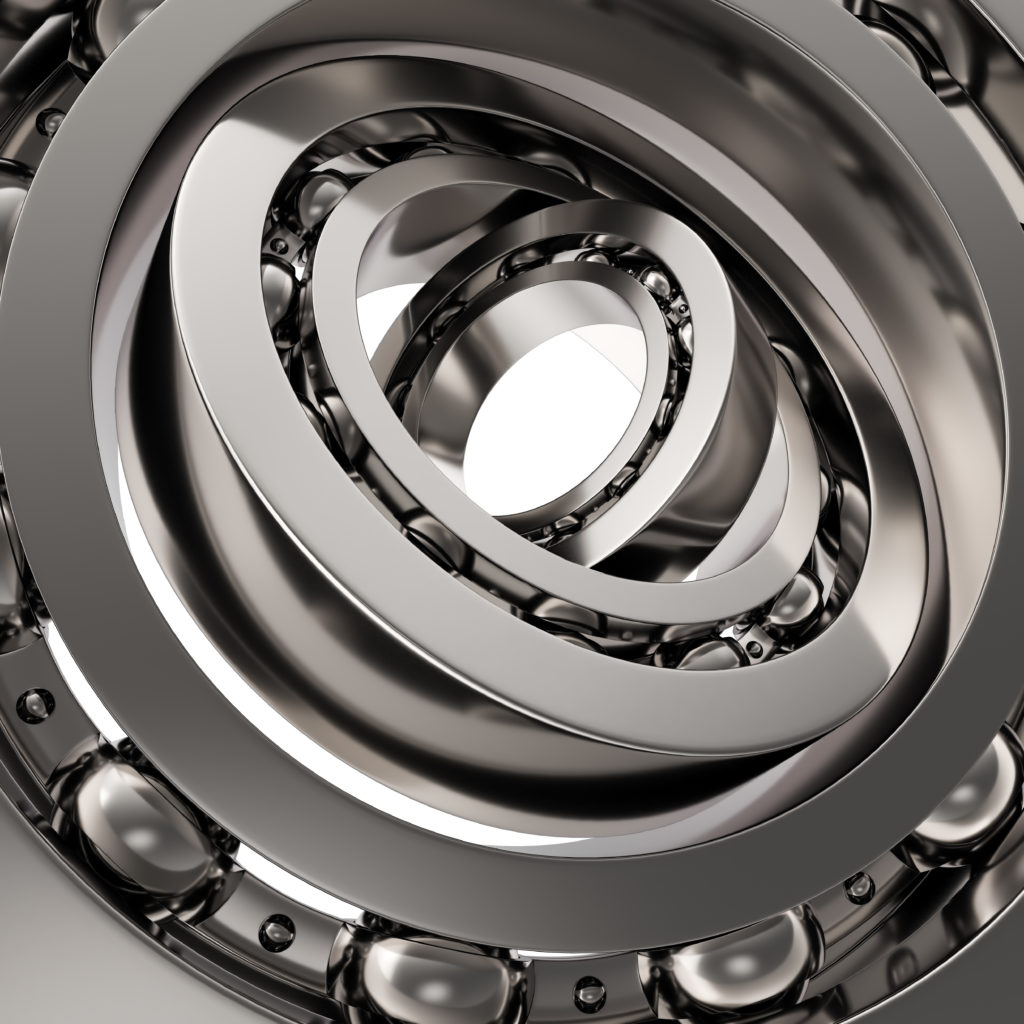

Silver Bearings

Engines operating continuously at high temperatures require a strong durable type of bearing such as those coated with silver.

When steel ball bearings are electroplated with silver, they become stronger than any other type of bearing. Jet engines, for example, rely on silver bearings because they can function continuously and at very high temperatures without breaking down.

Not only is a silver-coated steel ball bearing robust, but the silver acts as a lubricant, reducing friction between the bearing and its housing. This increases the performance and longevity of the engine. Moreover, in the event of an oil pump failure silver-plated bearings provide enough lubrication to allow a safe engine shutdown before the mechanism seizes up and causes permanent damage.

Silver in Medicine

Even before medical science fully understood how silver works as a non-drug antibiotic, the metal was used to prevent the growth of dangerous germs. On long ocean voyages, for example, silver coins were dropped into water and wine casks to keep the liquids fresh. For decades, physicians placed several drops of silver nitrate into newborns’ eyes to prevent infection.

During World War I, battlefields wounds were wrapped in silver foil and silver sutures were used to close deep wounds.

More recently, medical devices such as breathing tubes, prosthetics and catheters are coated with silver to help fight infections. Silver is also being applied to artificial bones and scaffolding used to keep bones in place while they mend. Silver is found in bandages and ointments because it keeps bacteria at bay, allowing the body to heal faster.

Silver has also been shown to be effective against bacteria that are becoming drug resistant because of overuse. For example, a life-threatening Staph germ called MRSA (Methicillin-resistant Staphylococcus aureus), often referred to as a “superbug” and found in healthcare facilities, is becoming resistant to most antibiotics. To fight back, many facilities are employing silver-imbedded equipment including surgical tools, needles, stethoscopes, furniture, door handles, furniture, linens and even paper files.

Only during the past few years have scientist learned how silver works as a biocide. Silver ions can penetrate the cell walls of bacteria – without injuring mammalian cells – thus destroying the chemical and structural bonds essential for the bacteria’s survival and growth. In some special situations, silver is used to breach a cell wall thus allowing a drug to enter and kill the cell.

For more information on silver and medicine, see Silver in Medicine Backgrounder.

Silver and your Automobile

As motor vehicles become more computerized, silver is playing a vital role in their operation. Over 60 million ounces of silver are used annually in motor vehicles.

For example, every electrical connection in a modern car is activated with silver-coated contacts that start the engine, open power windows, adjust power seats, close a trunk and power on and off other features.

The demand for silver by automakers has led to projections of nearly 90 million ounces of silver absorbed annually by the industry by 2025.

To provide a better understanding of silver’s important function in the automotive sector, see our report titled, “Silver’s Growing Role in the Automotive Industry.” The report examines trends in automotive production, including the evolution of hybrid and electric vehicles. It also addresses transportation policies that favor vehicle electrification in some of the world’s most important vehicle markets. The report provides an analysis of silver automotive demand in a range of vehicles and the growing importance to silver demand of ancillary automotive services. The report concludes with an assessment of current and forecasted silver demand in automobiles through 2025.

Silver in Water Purification

Millions of water purifiers are sold each year and silver is inside many of them. Silver prevents bacteria and algae from building up in their filters so that they can do their job — getting rid of bacteria, chlorine, trihalomethanes, lead, particulates and odor. Silver, in concert with oxygen, acts as a powerful sanitizer that offers an alternative to, or an augmentation of, other disinfectant systems.

Silver ions are being added to water purification systems in hospitals, community water systems, pools and spas. Silver also helps to prevent Legionnaires’ disease, which is caused by buildup in pipes, connections and water tanks.

Water-born illness is a major problem in developing nations. The full extent to which silver can help treat the issue of clean drinking water has yet to be seen, but ongoing research is showing its usage to be an exciting development for the global water supply.

Silver in Photography

The popularity of digital photography has all but replaced film photography among consumers and professionals. As a result, the use of silver-based imaging has been steadily dropping for many years. However, the move to digital has spurred a retro movement with photographers embracing traditional silver halide film which they claim offers finer detail and more robust colors. Within this group are those favoring instant photographs like those first pioneered by the Polaroid company in the 1940s. Even though large-scale commercial production of instant film ended in 2009, film for these cameras is available from the Impossible Project, which not only produces new instant film but also manufactures new cameras and refurbishes used ones.

Despite the growth in digital photography, silver-based film is still sometimes used for X-Rays, making use of existing equipment that continues to supply extremely accurate images. Silver-based films are also the medium of choice for some commercial movies because of their vibrant colors and high resolution.

The George Eastman Museum in Rochester, New York, preserves and develops world-class collections related to photography and cinema. You can view many of exhibitions online, and learn about the rich history of silver-based photography here: George Eastman Museum